ANGIOPLASTY DRAPE MANUFACTURE

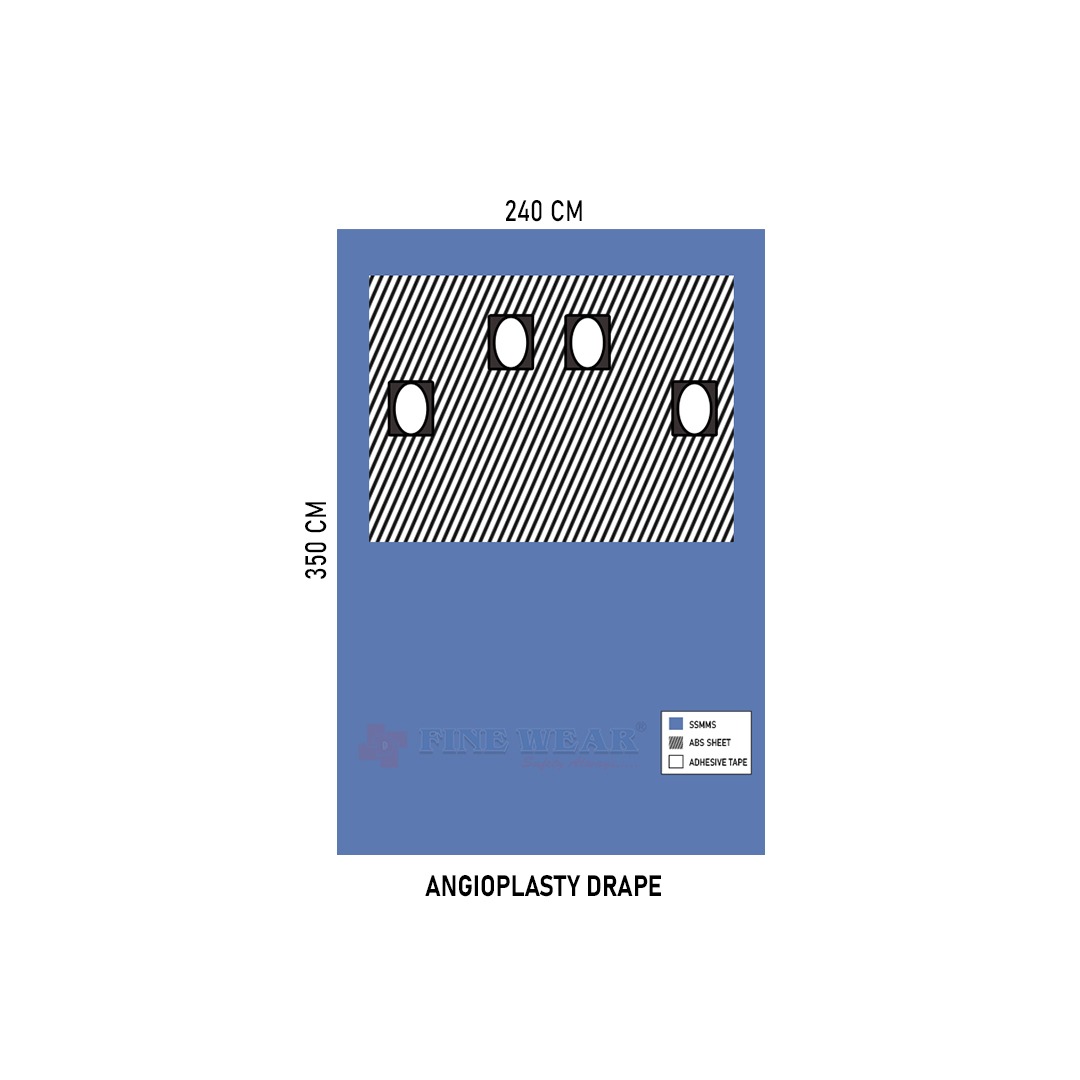

With Absorbent Reinforcement 240x350cm, 2 Adhesive Apertures 15 cm – 1 pc

Stripes – 4 pcs

Wrap – 1 pc

We Will Delve Into The World Of Angioplasty Drapes, Exploring Their Manufacturing Processes, Quality Standards, And The Crucial Aspect Of Exporting Them To Meet Global Healthcare Demands.

Angioplasty drapes are manufactured and sterilized to meet the highest standards of cleanliness. They ensure that the surgical field remains free from contaminants, reducing the risk of infections.

The drapes are crafted from hypoallergenic materials to minimize the possibility of allergic reactions or skin irritations in patients.

Many angioplasty drapes come equipped with adhesive edges, which facilitate easy and secure application to the patient’s body. This helps in creating a barrier against contamination effectively.

Angioplasty drapes often feature strategically placed fenestrations or openings. These allow medical professionals access to specific areas while keeping the rest of the surgical field covered and sterile.

Keywords

rest

1 pc

risk

easy

body

World

access

barrier

Stripes

openings

patients

infections

4 pcs Wrap

possibility

cleanliness

contaminants

contamination

fenestrations

specific areas

adhesive edges

surgical field

Crucial Aspect

skin irritations

highest standards

Quality Standards

secure application

allergic reactions

2 Adhesive Apertures

medical professionals

Manufacturing Processes

Absorbent Reinforcement

Many angioplasty drapes

hypoallergenic materials

Global Healthcare Demands

ANGIOPLASTY DRAPE MANUFACTURE